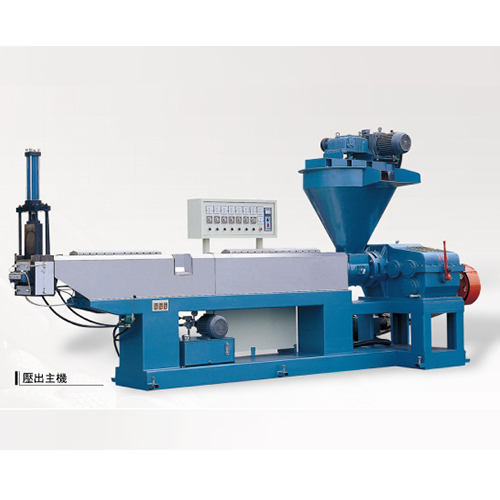

Plastic Pelletizing Machine / Pelletizer Extrusion Line

Categories : Plastic Pelletizer Machines

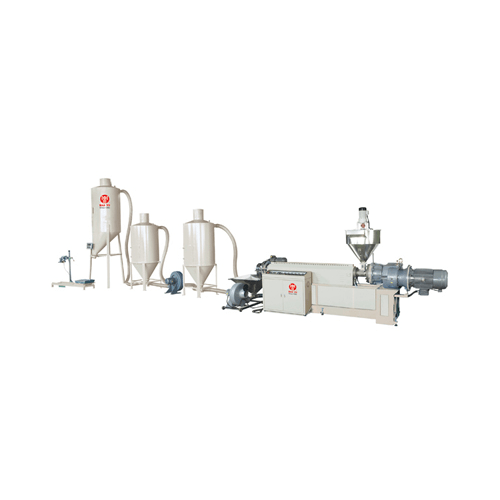

Optional Accessories:(1) Wood flour drier(2) Humidity tester(3) Chiller(4) Water cooling tower(5) Movable electronic balance with portable sewing machine (6) Wood flour grinder

Repet Wood WPC Granule Pelletizer Plant

Categories : Plastic Pelletizer Machines

Indoor & outdoor building material Outdoor furniture

Granulating System: Flow Channel of Plastic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

The plastic strand pelletizing system consists of a die, water-cooling channel, pelletizer, centrifugal hydroextractor and a circulating water-cooling system. Mainly used for plastic materials such as PET、PA、PC etc

Water-Cooled Type PVC Pelletizer

Categories : Plastic Pelletizer Machines

Water-Cooled Type PVC Pelletizer

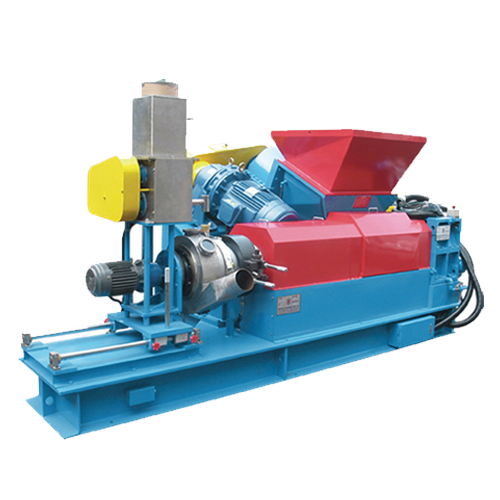

Twin-Cone High Speed Pelletizing Machine-Die-Face Cutting

Categories : Compounding Lines

Process Rubber/Plastic mixed material, EVA, TPR, PVC, CaCO3, PVB, PU, TPU compounding, various kinds of masterbatches pelletizing High capacity Low electricity usage Easy to clean and change materials Knead well Die-face cutting Adequate kneading

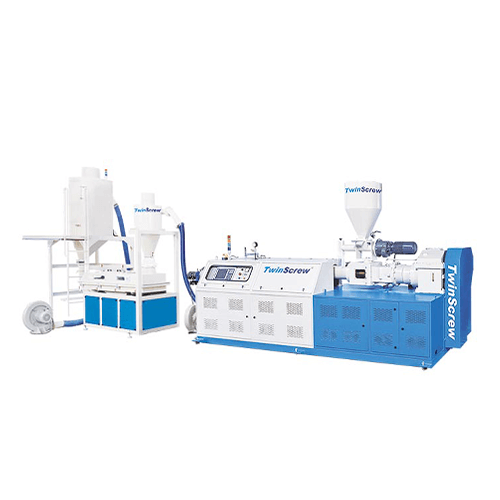

Twin Screw PVC / PBAT / PBS Pelletizing Machine

Categories : Plastic Pelletizer Machines

●Twin Screw Extruder ●Die Face Cutting ●Vibration Cooler ●Silo Tank

Granulating System: Underwater Pelletizer

Categories : Plastic Pelletizer Machines

Underwater pelletizer with advanced water cooling technology. Energy saving, Easy Operation Underwater Pelletizing System. Mainly used for plastic materials such as PP、TPU、TPR、TPE etc.

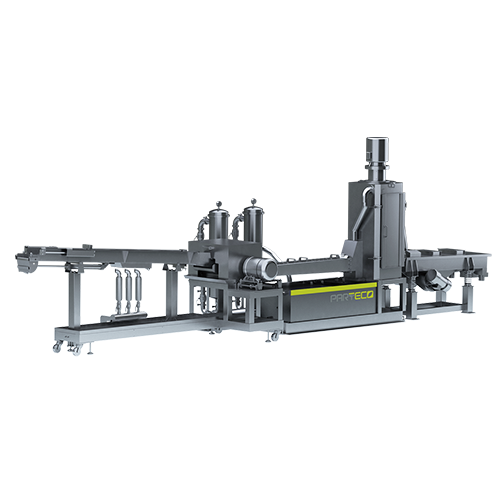

Granulating System: Strand Pelletizer

Categories : Plastic Pelletizer Machines

Advanced strand pelletizer for most plastic materials. Specialize in manufacturing of the plastic strand pelletizing system. PARTECO plastic granulating machine is applicable to most of plastic materials. Suitable for most plastic materials.

Hot Die Face Pelletizing System

Categories : Plastic Pelletizer Machines

Cost Reduction The molten polymer from the extruder is passed to the die head. A rotating blade cuts the hot material as it exits the die hole and falls into a water ring for cooling. The operator does not need to draw the strands, which reduces the lump waste during re-drawing. More Uniformity, More Profit The pelletizing cutter is a universal joint design. The cutter adjusts the blade automatically during operation. Final plastic pellets are in uniform size in order to be sold at a higher price and bring you more profit.

3-in-1 Plastic Recycling and Pelletizing Machine

Categories : Plastic Pelletizer Machines

The machine consists conveyor, shredding drum, extruder and pelletizer to integrate the production to minimize working time and save the manpower.

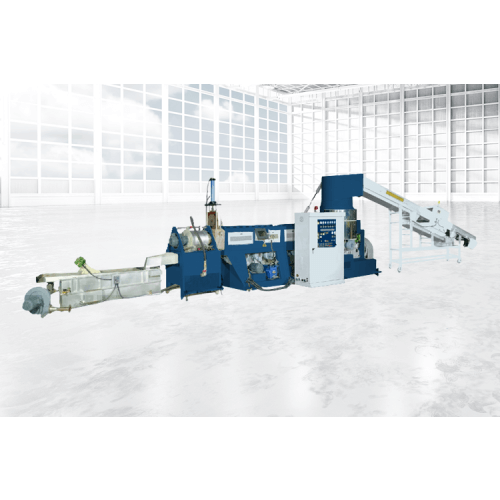

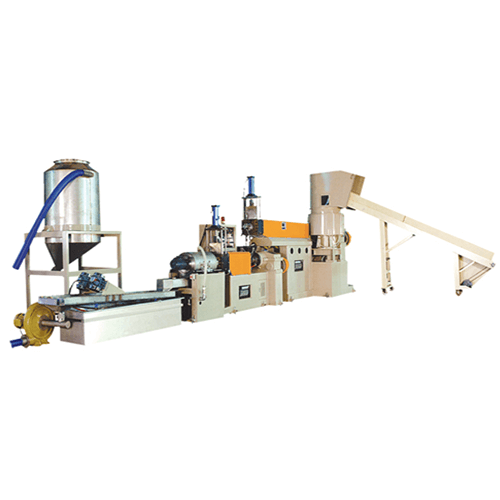

Side Entrance Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Feeding production is more stable than traditional force feeding. Able to open a input hole on top of barrel to conduct feeding formula and master batch pellets. It's a useful and productive type. Crusher is optional. With forced feeding hopper allows the machine to input two kind of material.

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean

Pelletizing & Recycling System

Categories : Plastic Pelletizer Machines

MGB-RPW-65 For PP, HDPE and LLDPE recycling.

Granulating System: Water Ring Pelletizer System

Categories : Plastic Pelletizer Machines

Structure and function of our plastic water ring pelletizer system and machine. Features and advantages of our plastic water ring pelletizing machine line. Applicable plastic materials of our plastic granulating series system and machine. Mainly used for plastic materials such as LDPE、HDPE、PP etc.

Twin-Cone High Speed Pelletizing Machine-Underwater Cutting

Categories : Plastic Pelletizer Machines

Suitable for high viscosity raw materials, such as PP, PMMA, TPU, PU, PLA, PET, TPU, PU, PLA and etc. High viscosity raw material. High Capacity, Low electricity usage, Easy to clean and change materials, Knead well, Underwater cutting

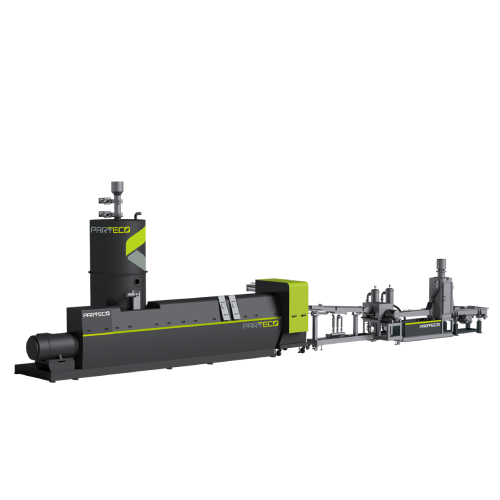

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pelletizer Machines

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly applied to the processing of PET crushed chips recycled from PET bottles. By means of vacuum degassing system to remove the water and impurities, then go through the melting extrusion, filtering and granulating process to tailor made the complete PET recycling solutions for you. Applicable materials Film or Flakes : PET Bottle Flakes

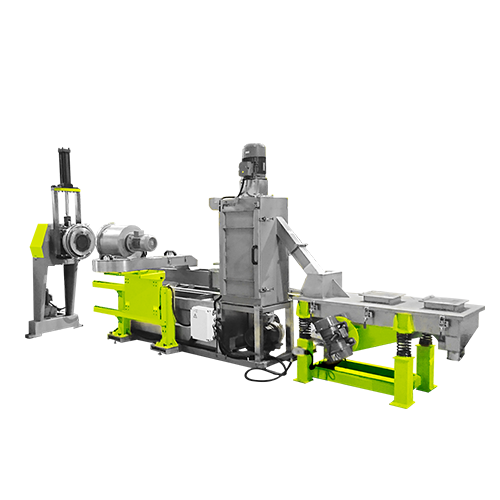

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

Extrusion & Pelletizing for Rubber、Plastic & Chemical Industries This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

Water Cooling Pelletizer Line (Horizontal Type)

Categories : Plastic Pelletizer Machines

WATER COOLING PELLETIZER LINE (HORIZONTAL TYPE)

Water Cooling Pelletizer Line (Vertical Force Type)

Categories : Plastic Pelletizer Machines

WATER COOLING PELLETIZER LINE(VERTICAL FORCE TYPE)

Three In One Cooling Pelletizing Machine

Categories : Plastic Pelletizer Machines

Three In One Cooling Pelletizing Machine

High-Speed Dyeing & Pelletizing Production Line

Categories : Compounding Lines

Suitable for masterbatch with fiber pelletizing, HDPE, LLDPE, LDPE, PP, PMMA, ABS, PC, Nylon, etc. Special screw design for compounding Changing material is easy Easy to operate Machine frame is very strong Customized screen changer

HF-FTO 3 In 1 Series:3 in 1 Pelletizing Extrusion / Extruder Pelletizer

Categories : Plastic Pelletizer Machines

Produced by experienced plastic recycling extruder machine manufacturer. Suitable for handling differences of materials. Suitable for processing most of the thermoplastic materials. Applicable materials Film or Flakes : PE、LDPE、LLDPE、HDPE、PP、PET、PS、PA、BOPP、ABS

SIDE FEEDING & DIE FACE CUTTING PLASTIC RECYCLING & PELLETIZING MACHINE

Categories : Plastic Pelletizer Machines

Suitable for both soft and hard plastics (films, bags, flakes, bottles, yarns and injection molded materials) Easy operation & maintenance Special design of die face and cutter ensuring uniformity of pellet size and lengthening blade's lifespan Stable production capacity of high-quality granules 20% lower energy requirements than other models One-person operation and less labor costs

Inline Edge-Trim Recycler (JC-ECOTRIM Series)

Categories : Plastic Pelletizer Machines

JC-EcoTrim Series - Inline Edge Trim Pelletizing Unit was introduced on the basis to the subject of “Green Eco-Friendly” awareness to the film production industry. The unit cleverly integrated advanced structural design with innovative concept for pelletizing and reclaim of trimmed film edge uninterruptedly within its system. The process starting from edge trim feeding, plasticizing, pelletizing, cooling, and reclaim, all in one complete procedure promised to save labor cost, power consumption and process time.